Lucid's Next EV for Saudi Arabia: What It Signals for Local Manufacturing

- KEY TAKEAWAYS

- From Reassembly to Real Manufacturing

- Lucid's Saudi Manufacturing Evolution (2023-2026)

- The Gravity SUV Timing

- The Local Car

- Quality Control Standards

- Local Supply Chain Development

- Climate Adaptation Engineering

- Industry Impact

- Employment and Skills Development

- The Export Strategy

- Conclusion

Lucid Motors is taking its next manufacturing steps at its King Abdullah Economic City facility in Saudi Arabia. What started as basic reassembly of Arizona-imported car kits has now expanded significantly. The plant added 7-8 new buildings and is transitioning from semi-knocked-down (SKD) assembly to full-scale manufacturing, with complete production lines capable of building vehicles from the ground up targeted within the next few years.

KEY TAKEAWAYS

What's Lucid building next in Saudi Arabia?

Lucid is planning a new, more affordable midsize EV for production at its Saudi KAEC factory.How does this differ from current operations?

Current SKD reassembly transitions to CBU full manufacturing with local parts and complete production.This milestone marks Saudi Arabia's transformation from a car importer to becoming a manufacturing automotive hub. Vision 2030's manufacturing goals for local car production now feel real. Lucid's move establishes PIF's $3.4B investment into the project. The initiative also encourages other proposed plants from Hyundai, Ceer, and others to accelerate their local production plan. This is going to make a huge impact on Saudi Arabia’s automotive industry with its manufacturing base. For buyers, cheaper locally made EVs are possible, but the real question is can Saudi Arabia master the supply chains and workforce needed to sustain its local manufacturing ambition?

From Reassembly to Real Manufacturing

Lucid's initial Saudi operation was deliberately conservative. The company started building cars completely in Arizona, which were then disassembled, shipped as kits, and reassembled in Saudi Arabia. This allowed several key aspects of manufacturing in the plant, like training of workers, facility testing without risking quality, and slowly getting the local base ready. This has progressed into workers successfully handling the assembly of 16-20 vehicles every single day.

After doing this basic assembly for a considerable time, this phase is ending. As the plant prepares to move to the next level and gears up to install equipment for complete vehicle production. These include paint shops, body assembly lines, battery integration, and powertrain installation, all elements of a proper car factory, which is expected to take off by late 2026.

This transition is a big step for the company, as it's real industrial capacity, not basic, lower-level assembly anymore. When complete, Lucid plans to manufacture 150,000 vehicles annually entirely within Saudi Arabia using locally sourced components where possible.

Lucid's Saudi Manufacturing Evolution (2023-2026)

|

Phase |

Timeline |

Operation |

Capacity |

Employment |

Local Content |

|

Phase 1 |

Sep 2023-2024 |

SKD reassembly |

5,000/year |

200-300 |

<10% |

|

Phase 2 |

2025 |

Transition to CBU |

20,000/year |

800-1,000 |

15-20% |

|

Phase 3 |

2026-2027 |

Full manufacturing |

150,000/year |

3,000-4,000 |

40% target |

The Gravity SUV Timing

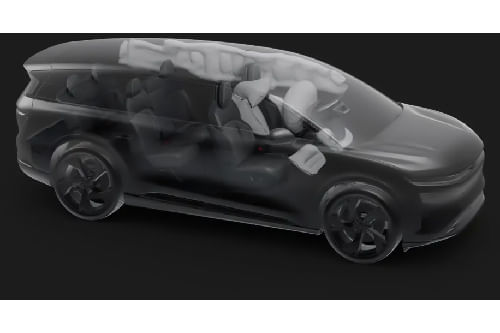

Lucid started the first phase of semi-knocked-down (SKD) assembly of the Lucid Air sedan since the operation kick-off of semi3. Now the EV maker is moving towards Gravity SUV production in Saudi Arabia, which is expected to take off by next year. The timing is strategic, as Gravity is Lucid's volume model, which is targeted at export to broader markets than the luxury Air sedan. Building it in Saudi Arabia from the start avoids later retooling and ramps up production.

Lucid Gravity specifications appeal to Saudi buyers:

- Three-row seating for families

- 440+ mile range addressing range anxiety

- 800V architecture for 20-minute fast charging

- Starting around $79,900 (approximately SAR 300,000)

- Export to GCC markets and beyond.

This is not an ordinary development, but the production of the SUV underlines Saudi Arabia's growing profile as a manufacturing location and enhances confidence in local production quality. With this step, Lucid is not reserving premium models for Arizona; rather, the Gravity competes directly with established luxury SUVs like the BMW iX, Mercedes EQS SUV, and Tesla Model X, all of which are currently imported to Saudi Arabia. This makes them expensive with expensive shipping costs and import duties. Local production has huge advantages, like giving Lucid instant pricing over its competitors.

The Local Car

Quite literally and in a big achievement, Lucid became the first global automaker earning Saudi Arabia's Made in Saudi badge in early 2025, with Global Automakers Expanding Their Leadership Teams also. This certification requires meeting strict local content thresholds.

What "Saudi Made" means:

- Minimum 25% local value addition

- Use of Saudi components and materials

- Employment of Saudi nationals in production

- Technology transfer to local workforce

- Compliance with Saudi industrial standards

Lucid achieved this in under two years through intensive workforce development and supplier recruitment.

Quality Control Standards

To make the transition to a manufacturing process often comes with concern about quality. Many buyers naturally feel concerned about whether Saudi-built Lucids match Arizona quality, but the EV maker addresses this through strict standards.

The Saudi facility totally replicates Arizona's quality processes, which consist of all the steps like automated laser measurement, paint booth controls, battery testing, and over 300 inspections at various stages. Every vehicle undergoes identical validation regardless of production location, and this has been confirmed by early customer feedback that there are no quality differences between US- and Saudi-built cars. Giving a big boost to the local manufacturing base and also enhancing customers' confidence in the cars.

Local Supply Chain Development

If Lucid wishes to reach its stated manufacturing goal of 150,000 vehicles annually, then it certainly needs domestic suppliers. It is not possible to import every component; it is not possible and also economically inefficient.

Lucid is developing Saudi suppliers for:

- Interior trim components and upholstery

- Aluminum body panels and structures

- Wiring harnesses and electrical systems

- Plastic molding and composites

- Glass and glazing components

Some of the key components which are high-technology ones, like batteries and motors, still come from global suppliers. But the percentage of locally sourced parts is rising. Vision 2030 targets 40% local content by 2030, which is huge, and work is underway to achieve it with changes like Saudi Arabia's New EV Policy.

Climate Adaptation Engineering

Unlike many other countries, manufacturing EVs in Saudi Arabia is not the same. This is primarily due to the extreme climatic conditions, and the temperature here exceeds well above 50°C, which is not normal anywhere. Such a high temperature is a huge challenge for battery cooling and cabin climate control. Lucid's Saudi engineering team developed specific adaptations to meet the need.

This required modifications, including improved battery thermal management, upgraded cabin AC, heat-reflective glass, modified charging algorithms for high temperatures, and extended battery warranty coverage. Interestingly and certainly quite importantly, all of this engineering work is happening right here in Saudi Arabia, and this is helping develop and expand technical expertise within the Kingdom.

Industry Impact

Lucid's transition, huge progress and rapid advancement clearly demonstrate Saudi Arabia 's perfect automotive manufacturing location. This is especially notable when a premium EV maker invests billions of dollars in full production, illustrating confidence in local capabilities.

This is likely to impact:

- Established manufacturers may look to set up local manufacturing.

- Chinese brands like BYD, MG & Zeekr could consider establishing operations

- New manufacturers attract major suppliers the country

- Automotive engineering talent will relocate

- EV technology transfer get boosts

The King Salman Automotive Cluster is becoming an actual industrial zone rather than a concept.

Employment and Skills Development

Lucid currently employs 800-1,000 workers, and this is expected to grow to 3,000-4,000 by 2027. These employees are not just assembly workers, but they are engineers, technicians, quality specialists, and managers.

To nurture and develop local talent, the EV maker has partnered with Saudi institutions for workforce development. Lucid also sends Saudi employees to Arizona for multi-month training, and they return with expertise in EV manufacturing and battery technology.

The Export Strategy

Lucid's Saudi facility is not going to serve just local demand. The company has plans to export to GCC countries, the Middle East, Europe, and Asia, which is the whole objective of its manufacturing base in the KSA. For its export ambitions, the Red Sea port location provides perfect shipping access.

Export markets being considered:

- UAE, Kuwait, Bahrain, Qatar

- Egypt, Jordan, Lebanon

- European Union

If Lucid successfully exports from Saudi Arabia, other manufacturers will view the Kingdom as a viable production base.

Lucid has received nearly $3.4 billion in Saudi government support over 15 years. This includes financing from the Saudi Industrial Development Fund and infrastructure from King Abdullah Economic City. Also, Saudi Arabia's Public Investment Fund owns over 60% of Lucid. The project is a strategic investment, and the Kingdom is doing everything in its power in order for the development of automotive manufacturing to succeed and consider Lucid as the major impetus for broader industry development.

Conclusion

Overall, Lucid’s arrival and then gradual transformation from reassembly to full manufacturing at King Abdullah Economic City showcase tremendous progress. At its peak, the plant will produce 150,000 vehicles annually, including the Gravity SUV, with 40% local content. The Made in Saudi certification underscores quality. This signals Saudi Arabia is building real automotive manufacturing, not just assembling imported components. All of this is going to help the country in a big way over decades, and it will eventually emerge as a key global auto hub with many automakers setting up their manufacturing footprint in the country.

Lucid Car Models

Don't Miss

Latest Car News & Expert Reviews

- Latest

- Popular

You might also be interested in

- News

Featured Car

- Popular

Compare & Recommended

|

|

|

|

|

|

Transmission Type

Automatic

|

-

|

Automatic

|

-

|

Automatic

|

|

Power

-

|

-

|

550Hp

|

1020Hp

|

503Hp

|

|

Torque

-

|

-

|

820Nm

|

-

|

-

|

|

|

Trending SUV

- Latest

- Upcoming

- Popular